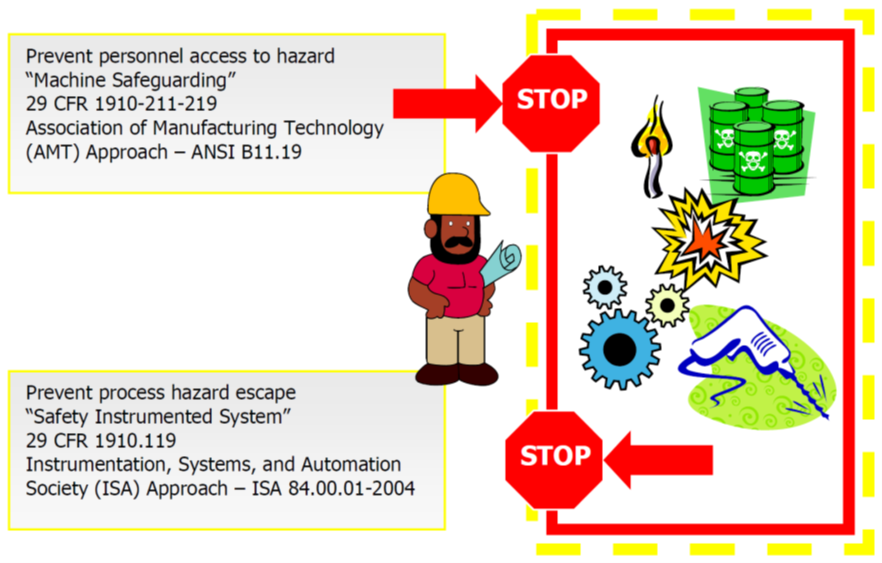

Industry has applied instrumentation and control devices for the

purpose of safeguarding people, equipment, and business for almost

as long as instrumentation and control has been used – that is machine safeguarding and safety instrumented systems. In the “wet”

process industries these devices and systems have been employed to

detect out of control conditions in the process and take mitigative

action to move the process to a safe state (i.e., safety instrumented systems). In the “discrete”

manufacturing industries instrumentation and controls have been used

to prevent personnel from exposing themselves to sources of danger,

such as hazardous motion, by either interlocking barriers to prevent

access to the hazard while it is present or remove power from the

hazard when personnel come into close proximity (i.e., machine safeguarding).

As industry matured and instrumentation and control systems evolved

and became more standardized, regulators and industry groups

promulgated standard practices and regulation that define how these

systems should be implemented. This web of regulations and

standards was built from the perspective end use, as opposed to the

instrumentation and controls that are employed in the safety

functionality. As a result, there is now a large number of guidance

documents for the implementation of safety instrumentation and the

determination of which documents apply to which application projects

has become difficult. This situation is further exacerbated by the fact

that much of the engineering for these protective instrumented

systems is being performed by outside engineering contractors and

systems integrators who do not have an end user’s perspective on the

equipment under control. In fact, these outside contractors often

perform projects using a common set of equipment (for instance, a

limit switch de-energizing a motor starter) where the basis, in

standards, for the design varies from client to client and even from

project to project for a single client.

Kenexis has prepared a downloadable white paper to assist end users, engineering

contractors, and systems integration firms to determine which

standards and regulations apply to the systems they are designing.

The paper does this by providing an overview of the standards and

regulations that apply to safety instrumentation and a process for

determining which of those will apply to a specific project by analyzing

the nature of the equipment under control (EUC) and the level of risk

reduction that is required of the instrumented systems that are being

proposed for protection.

Download the Basis of Machine Safeguarding Requirements White Paper