Safety Requirements Specifications Training

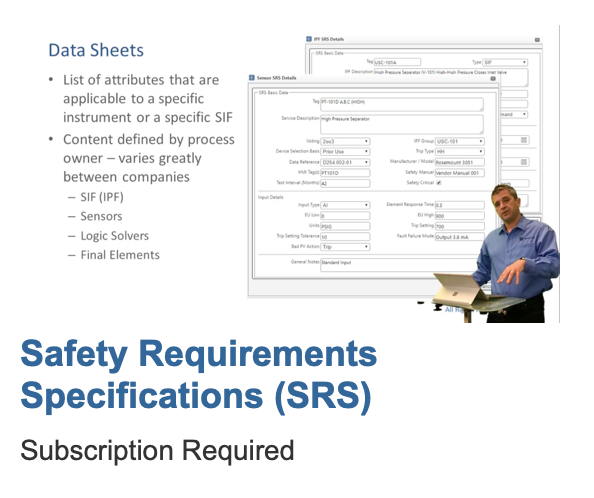

Kenexis has just expanded its Process Safety Training Center to include the just completed course on Safety Requirements Specifications. According to Kenexis President and CEO Ed Marszal, Safety Requirements Specifications are the weakest link in the SIS functional safety programs of most process industry organizations. He believes that most SRS documents that are prepared are written very poorly and making the problem even worse is the fact that very often the SRS step of the SIS safety lifecycle is completely ignored. The primary problem with SRS is that many practitioners, even self-proclaimed “experts” break the most fundamental rules of specification writing. The most common approach from industry “experts” which is often codified and automated in their software offerings is to treat the bullet point list of SRS requirements contained clause 10.3.2 of IEC/ISA 61511 as a “fill in the blank” form to be filled out for each safety instrumented function. Other than not preparing SRS documentation at all, this is the absolute worst way to prepare specifications. This approach ignores the needs of the wide variety of users of SRS document information and violates fundamental rules of specification writing like “don’t include operating instructions in equipment specifications” and “don’t specify the same information in multiple locations”. The Kenexis SRS training course goes into detail not only on what the standard requires you to include, but also provides discussions of the strengths and limitations of the various options that are available to you in the design process and best practices for preparing your documentation. This course is 100% dedicated to the qualitative aspects of design without any discussion of probability of failure on demand calculations – which are thoroughly discussed elsewhere.

The SRS source is just one part of the Process Safety Training Center, which includes dozens of training courses on SIS and technical safety topics, all for a fixed annual fee of $600 per person. Compare this to taking just one class for $2,000 to $3,000 at other venues. Check out the Process Safety Training Center.